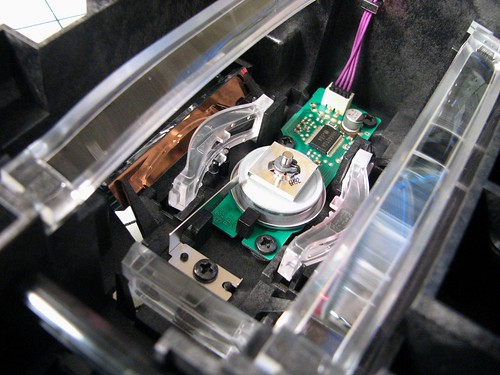

Recent print engine design for color laser units is different in a sense that all toner cartridges are fixed and stationary, and arrayed either vertically or horizontally. Moreover, the cartridge alignment makes it impossible for cartridges to supply toner to a single OPC Drum. Designers added 4 OPC Drums and 4 Laser Scanning Assemblies - one for each cartridge. And what better way to make the process work but to attach the toner cartridge assembly to the OPC Drum component. This results to better printouts delivered at a much faster turnout. In line with the new print engine design, the OPC drum is now housed together with the toner cartridge. So when the cartridge runs out of toner, the user technically replaces not only the cartridge but also the OPC Drum.

Solo cartridges produced in the past were already very expensive. Well, the new toner and OPC Drum cartridge combo is even more pricey. But one simple fact remains. The lifecycle of the OPC Drum is at least 3 times or more than that of the toner cartridge. The Dell 310-54808 toner cartridge (yellow) is rated 8,000 pages at 5% coverage and the OPC Drum has a life expectancy of over 30,000 pages; also at 5% coverage. Every time a user discards an empty cartridge combo, the OPC Drum is also disposed even when the component has not even reached 20% of its full potential. And considering that the toner cartridge alone can last over 3 lifecycles, imagine how much money is wasted because the Dell OEM toner cartridge combo costs $210.

However, users can prevent the ‘printing blues’ by administering toner refills on the empty toner cartridge combo. Bear in mind that a compatible DELL 5100 toner refill kit sells for only $28.95 and since it is manufactured along similar lines with the OEM toner, it is guaranteed to perform at par with the genuine cartridge. Moreover, the user can institute refills on an empty cartridge several times over the industry recommended refill frequency. This way, substantial savings could really be generated.

So, why do OEM color toner cartridges cost so much? To reiterate, the consumable has evolved to a toner cartridge and OPC Drum duo.

A perfect example of compatible toner that meets or even exceeds industry standard is the toner supplied with the

A perfect example of compatible toner that meets or even exceeds industry standard is the toner supplied with the